Application of High-Voltage Amplifiers in Research on Macro-Fiber Composites

Experiment Name: Noise and Vibration Control of Composite Sandwich Panel Structures

Research Direction:

Piezoelectric materials, as a crucial component of smart materials, have gained significant research attention due to their advantages such as excellent durability and strong environmental adaptability. Macro-Fiber Composite (MFC), with its high flexibility and substantial output force, is a novel high-performance piezoelectric smart material. MFC primarily consists of three parts: piezoelectric ceramic fibers, an epoxy resin matrix, and interdigital electrodes. Its inverse piezoelectric effect can be utilized to fabricate actuators, while its direct piezoelectric effect is suitable for sensors. MFC is well-suited for lightweight structures, particularly in the active vibration control of panel and shell structures.

Experiment Objective:

To investigate the vibration control effectiveness of MFC on sandwich panel structures and validate the efficacy of the LQG/LTR active control algorithm with loop transfer recovery. By comparing sandwich panel structures with and without PMI foam filling, analyze the performance differences between embedded and externally bonded MFC in vibration control.

Test Equipment:

High-voltage amplifier, signal source, inertial exciter, signal conditioner, piezoelectric accelerometer, MFC actuator, dSPACE real-time simulation system, etc.

Experimental Process:

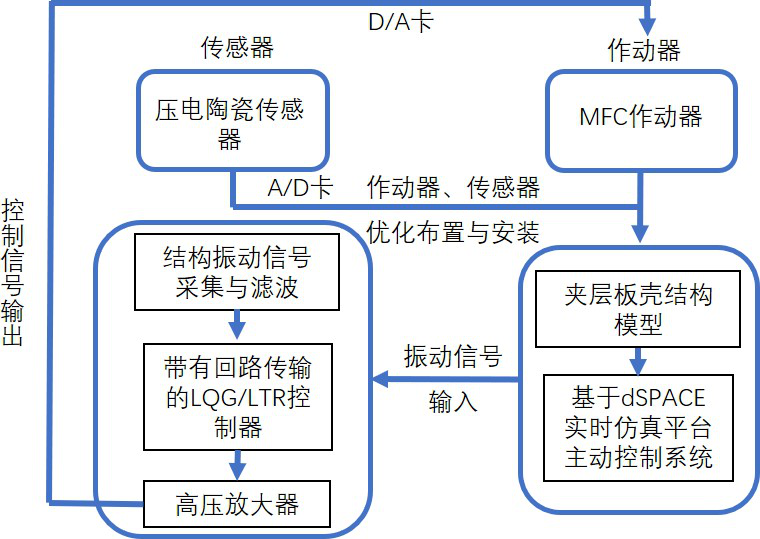

Figure: Technical Flowchart of Vibration Control Experiment

Establish the vibration control system for the sandwich panel structure and integrate MFC.

For the sandwich panel structure without PMI foam filling, attach one MFC externally to the outer surface of the top layer.

For the sandwich panel structure with PMI foam filling, integrate two MFCs—one embedded and one externally bonded. The embedded MFC is placed at the interface between the PMI foam and the carbon fiber surface layer, while the externally bonded MFC is attached to the outer surface of the top layer.

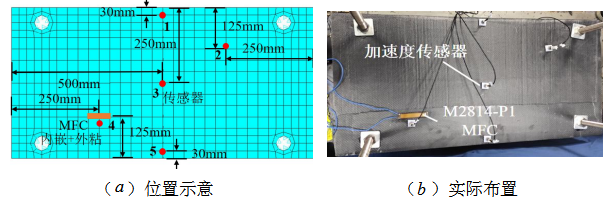

For the unfilled sandwich panel structure, position the MFC actuator according to the optimized actuator placement, followed by the piezoelectric accelerometer, as shown in Figure 2.

Figure 2: MFC and Sensor Placement in Unfilled Sandwich Panel Structure

For the filled sandwich panel structure, position the piezoelectric accelerometer according to the optimized sensor placement. To compare the control effects of externally bonded and embedded MFC integration methods, adjust the MFC actuator positions accordingly, integrating both methods at the same location, as shown in Figure 3.

Figure 3: MFC and Sensor Placement in Filled Sandwich Panel Structure

For the unfilled sandwich panel structure, select the first three natural frequencies (69.10 Hz, 79.90 Hz, 86.00 Hz) as excitation frequencies, with a sinusoidal excitation waveform.

For the filled sandwich panel structure, select 100 Hz, 125 Hz, and the first natural frequency (143.02 Hz) as excitation frequencies, with a sinusoidal excitation waveform.

Experimental Results:

Figure 4: 100 Hz Excitation Frequency

As shown in Figure 4, under externally bonded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 15.14%, and at the center of the PMI foam by 13.48%. Under embedded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 32.97%, and at the center of the PMI foam by 26.95%.

Figure 5: 125 Hz Excitation Frequency

As shown in Figure 5, under externally bonded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 13.79%, and at the center of the PMI foam by 17.27%. Under embedded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 29.13%, and at the center of the PMI foam by 27.92%.

Figure 6: 143.02 Hz Excitation Frequency

As shown in Figure 6, under externally bonded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 30.40%, and at the center of the PMI foam by 29.51%. Under embedded MFC actuation, the acceleration response at the center of the sandwich panel structure is reduced by 50.10%, and at the center of the PMI foam by 47.56%.

Figure 7: White Noise Excitation

As shown in Figure 7, under embedded MFC actuation, the reduction in acceleration response at the center of the sandwich panel structure is greater than under externally bonded MFC actuation.

For the PMI foam-filled sandwich panel structure, the reduction in acceleration response amplitude under 100 Hz and 125 Hz harmonic excitation is 12.25%–16.04% lower than under 143.02 Hz excitation. This indicates that the vibration reduction effect of the control system is better at natural frequencies than at non-natural frequencies. The control effectiveness of embedded MFC is 10.65%–18.05% higher than that of externally bonded MFC, demonstrating that embedded MFC provides superior actuation performance.

Recommended High-Voltage Amplifier:

Figure: ATA-2082 High-Voltage Amplifier Specifications

This document is compiled and published by Aigtek. For more case studies and product details, please continue to follow us.

Hot News

-

Application of Power Amplifiers in Experiments on the Directional Emission Performance of Underwater Acoustic Devices

-

Application of Broadband Power Amplifiers in the Demodulation Experiments of Tunable Lasers

-

Application of Power Amplifiers in Capacitively Coupled Wireless Power Transfer Systems

-

Power Amplifier Drives Signal Transceiver Testing for Novel Long-Wave Communication Antenna

-

Application of ATA-4051 High-Voltage Power Amplifier in the Design of Bionic Underwater Acoustic Receivers

-

Application of Broadband Amplifiers in Ultrasound Reflection Imaging Studies of CMUT Arrays